How to remove inks from printing machinery

Q. We are a commercial and packaging printing company. We want to use an ultrasonic cleaner to remove inks (oil based inks, UV inks and waterbased inks) from anilox rollers, ceramic rollers and grease from machine parts. What are the recommended cleaning solutions detergents that you can recommend?

How to: Reduce Cleaning Time

Q. What can we do to reduce cleaning time? We want to be as optimal and thorough in our cleaning as possible.

A. At Alconox Inc we recognize that manual cleaning may take minutes, spray cleaning seconds, and soaking may take hours, possibly overnight, to achieve comparable cleanliness. Read more….

Disposal of Alconox Inc. Detergents

What is the proper way to dispose of your detergents? Detergent disposal in a proper manner is an integral part of a robust cleaning program regardless of scale or industry. Alconox Inc. detergents are biodegradable….

How to: Clean Circuit Boards & Electronic Components

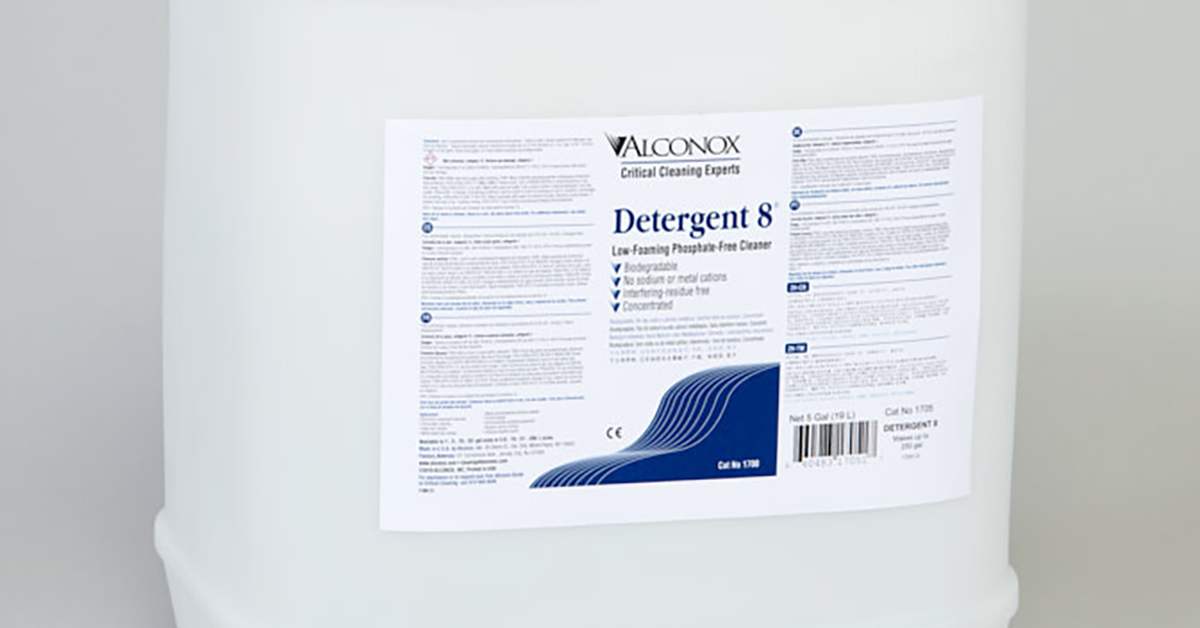

Learn how and when to clean circuit boards & electronic components with Detergent 8.

How To Choose a Phosphate-Free Clean In Place (CIP) Detergent

We are a biotech company looking to upgrade our cleaning with phosphate-free detergents used in CIP systems. We were recommended to contact Alconox Inc. Can you describe the uses of your low foam detergents, like Solujet, Tergajet and Detergent 8? Any others? What surfactants and cleaning constituents are there?