Q. We are currently writing a protocol for conducting a process validation activity for our cleaning procedures for metal parts after our machining manufacturing process. What are the differences between cleaning effectiveness of Alconox detergents for cleaning various metallic surfaces such as stainless steel, titanium and cobalt chrome? Also, does Alconox detergent effectiveness change based on contamination characteristics, surface geometry or any other factors?

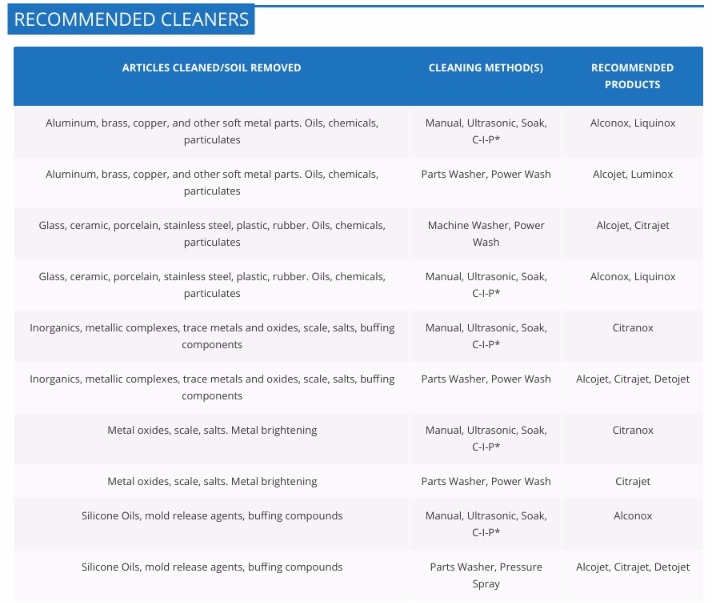

A. Generally speaking, Alconox® Powdered Precision Cleaner and Liquinox® Critical Cleaning Liquid Detergent, are very compatible across an array of metals. Below is a table for detergent recommendation by application for the Precision Manufacturing Industry. The table is also available for viewing on our Main Website. Note the some softer or more sensitive metal parts, including brass and freshly abraded aluminum, are better cleaned by acidic detergents such as Citranox® Liquid Acid Cleaner and Detergent. As outlined below, the residue will also determine the detergent.

In addition to detergent choice, there are several factors that are responsible for cleaning effectiveness. We offer an acronym to help clients keep each of these variable top of mind — “BATHOCARD.” Here are the factors and variables that influence cleaning outcomes:

- Before – handling prior to cleaning

- Agitation – type of movement used to enhance cleaning

- Time – duration of cleaning cycle

- Heat – temperature of cleaning solution

- Orientation

- Cleaner – chemistry of cleaning solution

- After – post cleaning handling

- Rinse

- Drying

It is important to understand and control these interrelated cleaning variables and understand how they influence critical cleaning. Details about how to better understand the influence these variables are available in our Critical Cleaning Guide.

In short, contamination characteristics, surface geometry and other factors may influence cleaning characteristics. As it always seems to be, the details are critical. We are pleased to discuss your particular application in detail.

To request an Alconox Inc. detergent for free, please complete the questionnaire at Get Sample. For more information about any one of our Alconox, Inc. detergents, consult the technical bulletin for each product. Or click here to access each of our detergent’s Safety Data Sheets.

Do you have a critical cleaning question for the experts at Alconox, Inc.? Search TechNotes to see if it’s been answered before or Ask Alconox.