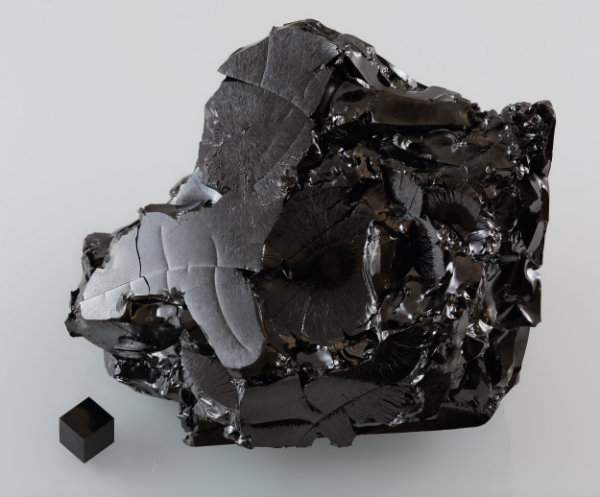

Cleaning Carbon Deposit Swirls On Alumina Parts

Q. Our parts, made of 99.5% alumina, have carbon deposits that show up after our brazing process. We do not use a flux for our ceramic parts; we high-temp fire a moly/manganese painted paste onto the ceramic. The part is then sent out for nickel plating to prevent corrosion of the moly manganese metallization areas. The next step is our brazing.

We are not seeing any spots on the parts before brazing, but as we continue through 5 brazing cycles and braze in a hydrogen/Nitrogen furnace with the cusil braze rings, we see black spots forming that show up as high-carbon deposits with the SEM data…

Removing Cutting Oil, Linoleic Acid from Parts

Q: Some metalwork pieces have a residue of linoleic acid (traced back to the cutting oil) that remains after ultrasonic cleaning with Alconox® detergent. Will Alconox® will fully dissolve linoleic acid? Can you recommend a cleaning process to ensure complete removal of all linoleic acid residue from our parts?

A: Alconox® Powdered Precision Cleaner will not dissolve, but will emulsify, the linoleic acid on your machined parts. In order to get a linoleic-acid-free clean, increase

Degassing Ultrasonic Cleaning Solution

Q. How would we determine appropriate degassing time for solution with ultrasonic cleaner? We are cleaning with distilled water with Alconox® detergent.

A. Degassing time varies with amount of dissolved carbon dioxide, which can vary. In general…

How Long for Residue Free Ultrasonic Cleaning?

Q. How to determine appropriate cleaning time to clean parts with ultrasonic cleaner?

A. Observations and cleaning trials are the best way to determine appropriate cleaning time. Many people use 10 minutes as a cleaning time. For difficult residues…