Oxidation or bleaching is one of the many cleaning mechanisms that a detergent formulator can bring to bear by formulating with appropriate ingredients. In cleaning, oxidation, or bleaching, changes the structure of a residue to render it more easily removed. Oxidation is loss of electrons in a chemical reaction. In the context of cleaning, the loss of electrons typically occurs by the gain of an oxygen by the oxidized residue, and the corresponding gain of an electron from the residue by the reduction of the oxidizing agent in the detergent that loses the oxygen.

In detergents the oxidizing agents are typically compounds such as bleach (sodium hypochlorite), bleach precursors that release bleach in solution (Dichlor), peroxide (hydrogen peroxide), or peroxide precursors that release peroxide in solution (sodium percarbonate).

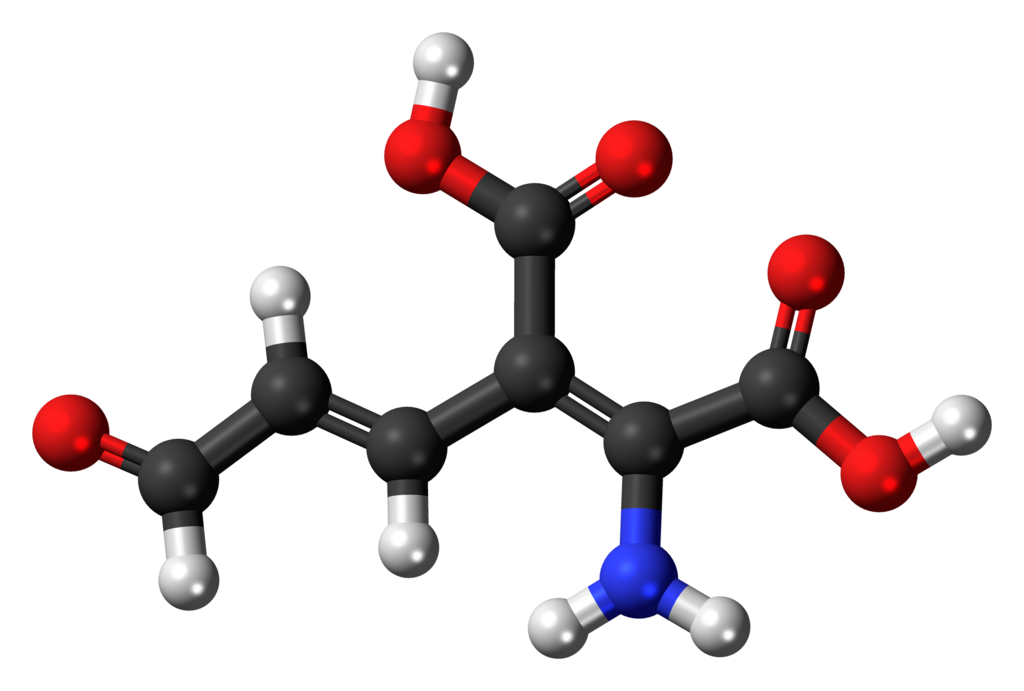

This means organic and bioresidues, found in the the medical device, cosmetic, healthcare, food and beverage, pharmaceutical, and biotech industries can be rendered easier to clean via oxidation or bleaching. The kinds of oxidation reactions that occur in biological and organic residues that render the residues more water soluble and easier to clean, are when oxidation breaks down double bonds. This leaves alcohol groups in their place which will typically render a molecule more polar, and therefore, more water soluble. Additionally, the double bonds that were converted to alcohols can further be broken and oxidized to separate pieces such as ketones and aldehydes. These compounds are smaller and more water soluble than the original residue.

The Alconox, LLC detergents that have bleaching agents in them are:

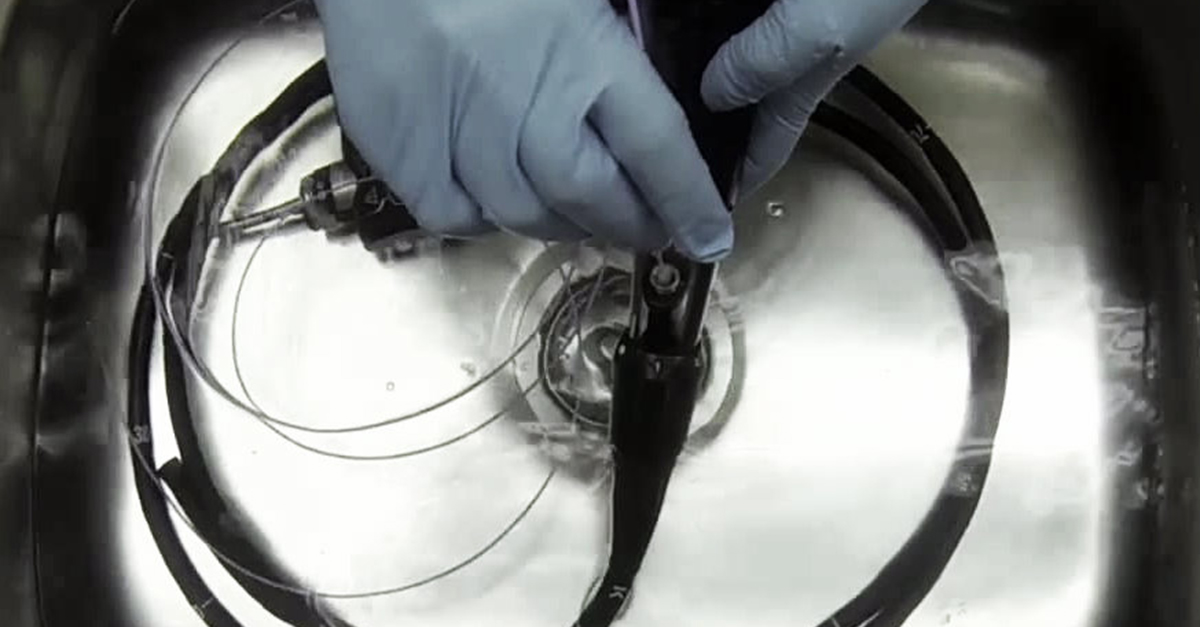

Oxidation is a reaction that occurs rapidly in a cleaning environment. For this reason, oxidative cleaning is useful for automated spray washing such as clean-in-place (CIP) spray balls, dishwashers, and cabinet washers. In these high agitation, high pressure cleaning environments, a droplet of cleaning solution spray that hits a surface only has a very short time to carry out a cleaning function before the next droplet of cleaning solution comes along and sweeps it away. All three of these detergents are low foaming detergents suitable for use in high agitation spray cleaning applications. This is not to say that you cannot or should not use these cleaners in manual, soak or ultrasonic cleaning. Oxidative cleaning can also be a perfectly effective cleaning mechanism to use in manual, soak and ultrasonic cleaning.

In very difficult cleaning applications, it can be useful to pretreat, presoak or preclean with a detergent that can bleach or oxidize, and start the cleaning process. Following which, in a second cleaning step, complete the cleaning process via critical cleaning detergents like Tergazyme® Enzyme Active Powder Detergent when soaking/scrubbing/sonicating, or Solujet® Low-Foaming Phosphate-Free Liquid if an automated spray washing system is next.

Oxidation is often quite helpful for organoleptic (aromatic/scented/taste) residues as well as color or dye residues found in cosmetic, food and beverage, cannabis and related industries. The aromas, tastes and colors often are related to double bonds and other oxidizable structures that are effectively cleaned by bleaching or oxidation. Again, this can be done through manual or automated means if these residues are in play.

To request an Alconox, LLC detergent for free, please complete the questionnaire at Get Sample. For more information about any one of our Alconox, LLC detergents, consult the technical bulletin for each product. Or click here to access each of our detergent’s Safety Data Sheets.

Do you have a critical cleaning question for the experts at Alconox, LLC? Search TechNotes to see if it’s been answered before or Ask Alconox.

What cleaning agent could you advise for cleaning copper products after machining during production?

Do you have an agent for protecting products against corrosion? mainly at machining process during standstill in the late hours. product has coolant on the surface.