Cleaning Machined PTFE Parts

Q. I just received your chapter on cleaning SOPs and I look forward to reading it. In parallel, I was hoping to get your thoughts or a bit of advice on how to create and implement cleanliness specifications/processes for machined (PTFE) plastic parts. Cutting fluid for the machining center is basically a water soluble vegetable oil-based fluid. The use of this plastic manifold and cover is within an electro-mechanical-fluidic subsystem (“Delivery Module”). This delivery module accumulates a quantity of 59wt% Hydrogen Peroxide that has been … Click to Read The Full Question and Answer.

Thin tube cleaning

Q. How can I use Citranox to clean thin tubes or needles?

A. To clean thin tubes, the best thing is to get cleaning solution flowing through the tubes. If you want to simultaneously clean the inside and outside of the tube, you need to flow solution through the tube under immersion. Learn More.

Industrial Laser Chiller Cleaning

Q. Chillers get scale build-up that reduce their heat transfer efficiency, thereby reducing their chiller performance. In particular industrial lasers need good chiller performance.

Therefore, use a 2% Citranox or Citrajet solution to remove calcium scale build-up. Be sure a 100 micron filter of adequate flow rating is installed in the coolant path. Be sure no galvanized pipe is in the system. Learn More.

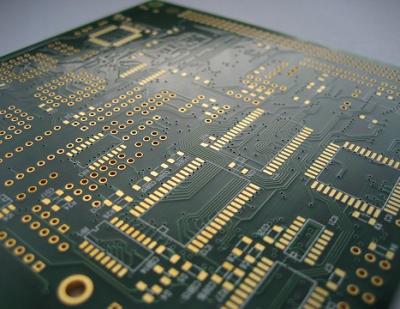

Cleaning Electronic Parts Prior to Soldering

Q. We need to clean parts to be soldered prior to applying solder. Do you have recommendations?

A. To clean parts prior to soldering you need to consider what residues you are trying to remove from the parts and how you want to clean. For general purpose oils and residue cleaning by manual, soak or ultrasonic cleaning methods, we recommend using a warm or hot 1% Liquinox solution . . .

Cleaning Aluminum without Corrosion

Q. How is galvanic corrosion prevented when cleaning aluminum?

A. Aluminum is an active metal that is somewhat high on the “anodic index” of the galvanic series. If aluminum is cleaned with other metals present, you can create a battery and get galvanic corrosion. Aluminum should not be cleaned in the presence of metals that are significantly higher or lower on the anodic series; higher on the anodic scale such as zinc, magnesium or beryllium metals and lower on the anodic scale such as tin, brass, bronze, copper, silver, nickel and rhodium.