Cleaning Automotive Pressure Sensors

Q. We make automotive pressure transducers. These are Stainless Steel automotive pressure sensors with baked on carbon and combustion deposits. Do you have a detergent recommendation?

All About Rinse Aids

There are basically three kinds of rinse aids: Hydrophobic rinse aids that leave behind a residue, surfactants that wet surfaces and allow rinse water to sheet off a surface without leaving behind droplets, and acid rinses that dissolve insoluble alkaline salt residues.

What is an Inhibitory Residue Test?

Q. What is an inhibitory residue test? A. The inhibitory residue test is a test of suitability of glassware for microbiology testing. Read more….

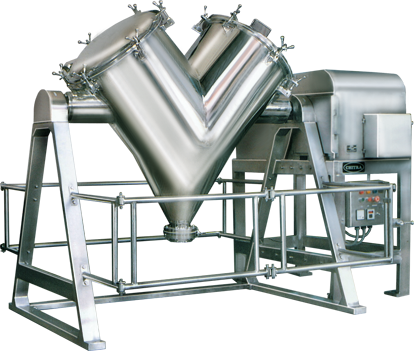

Cleaning a V Blender

Q. How would you clean a 3 cu ft V blender?

A: I recommend using a 0.5% Solujet® solution of 12 L to clean the 3 cu ft V blender followed by 2 rinses and then a 3rd sampling rinse. You may wish

Residue-Free Glassware Cleaner for Lab Washer

Q. I am currently looking for a residue-free glassware cleaner to use in our new lab washer. We would like to make sure that residue is not left behind on our glassware after washing. This is a normal portable dish washer that is typically used in the home. Could you recommend a detergent for us to use?