Cleaning Zinc Plated Metal Parts

Q. We would like to verify compatibility of zinc plated metal parts with Alconox. A. Zinc plated metal parts can be cleaned with Alconox detergent. Depending on the metal and whether there is any defect in the zinc plate coating, you can get galvanic reactions between the zinc and the underlying metal because…

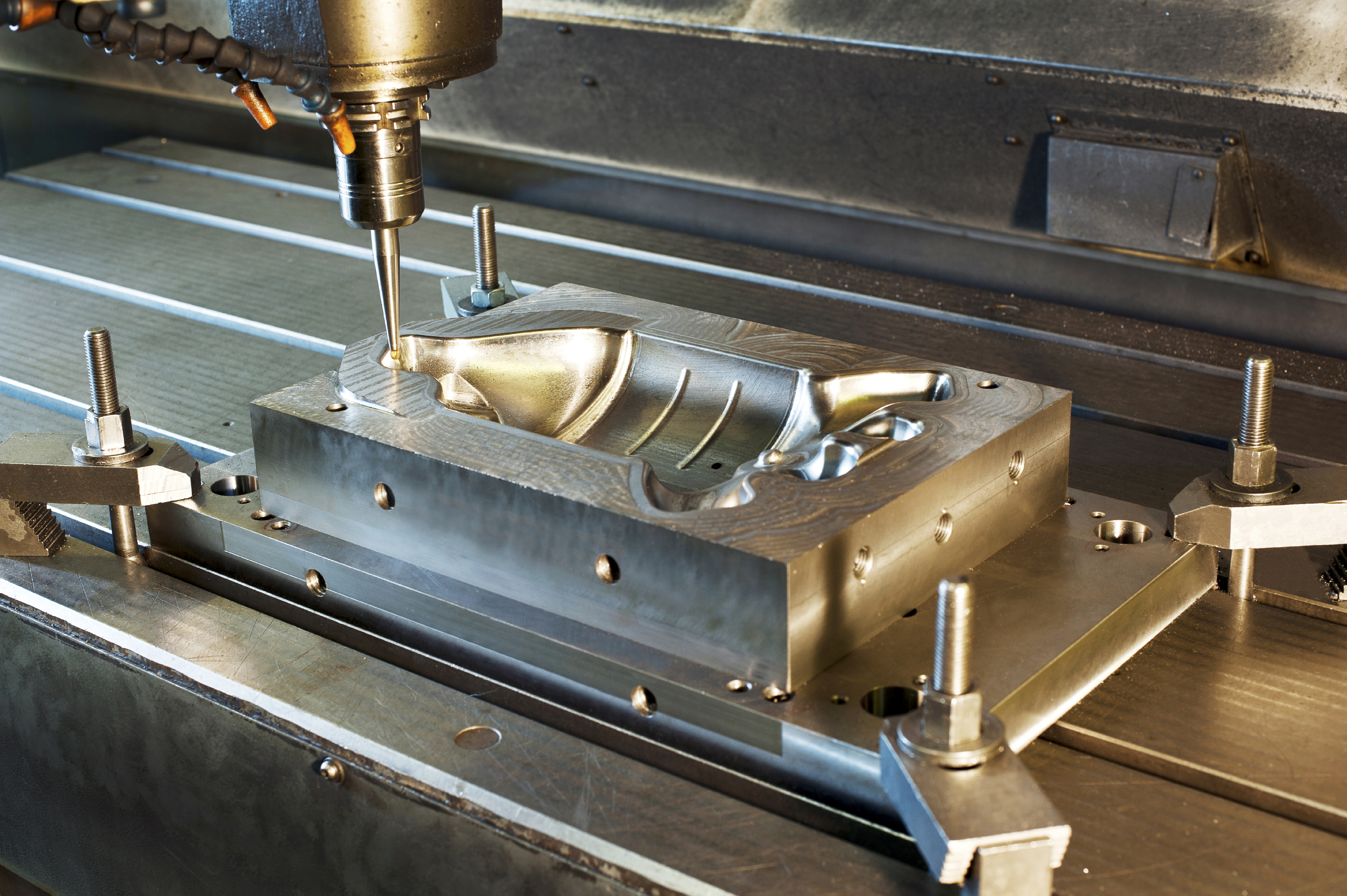

Cleaning Glass Castings: Alconox or Detonox?

Q. Q. We are having an issue plating aluminum on glass castings. It appears there is mold release left on the glass after the casting. The glass manufacturer recommended Alconox detergent. Is that what you would your recommend for cleaning the glass? Whatever we use, it probably needs to be a soak at a high temperature (>170°)? Is this procedure good or should we use an ultrasonic at the higher temperature?

Ultrasonic Cleaning of Glass Molds (Detergents vs. Alkali)

Q. We have heard that Alconox is recommended for glass mold cleaning. Other than release agent, can the product also remove oxidation from the mold surface? And finally, why is the concentration on the Alconox detergent only 1-3% when we typically use concentrations of 20-30% when cleaning molds with sodium or potassium hydroxide based chemicals?

A. Alconox® Powdered Precision Cleaner is what we tradtionally recommend for mold release cleaning applications, but many also find Detonox® Ultimate Precision Cleaner to be particularly effective.

When it comes to removing oxidation…

Visit Us at ADM Expo 2018 in Cleveland

See Alconox, Inc. at ADM Expo, Cleveland, OH, March 7-8, 2018. Stop by booth #216 to receive our unique gifts, expert technical support for your critical cleaning applications, and detergent samples.

Our critical cleaning detergents remove an array of soils while leaving no interfering residues in applications for precision manufacturing, medical device manufacturing, electronics manufacturing and more.

Filtering Detergent in Industrial Ultrasonic Cleaning System

Q: Is there a benefit to filtering the rinse water or the detergent solution in an ultrasonic system? Is it even advisable? If so, can you recommend a filter size (10 micron) when using Alconox detergent? This is for a new bath setup in a new piece of equipment.

A: My short answer would be, it cannot hurt but would likely be of limited assistance.