Q: Looking for a non-alcohol-based cleaner to remove a mold release from a hexavalent Chrome-plated part. What do you recommend?

A: For difficult mold release applications, we traditionally recommend high emulsifying detergents like Detonox® Ultimate Precision Cleaner and Liquinox® Critical Cleaning Liquid Detergent – How to Clean Mold Release Agent from HDPE parts?

However, hexavalent chrome can be reactive in electrolytic detergent solutions, especially if imperfection in the coating occur – Ultrasonic Cleaner for Mixed Metal Baths. Citranox® Liquid Acid Cleaner and Detergent, an acidic detergent, will greatly dampen that. Although not ideal for difficult organic, oily residue removal, Citranox itself may do the cleaning just fine.

For a low foaming option, for use in washers or high pressure spray systems, we would advise use of Citrajet® Low-Foam Liquid Acid Cleaner/Rinse to safely clean hexavalent chrome.

These are all alcohol free, non flammable, aqueous detergents that are free rinsing, biodegradable and drain safe.

What are Hexavalent Chrome-Plated Parts?

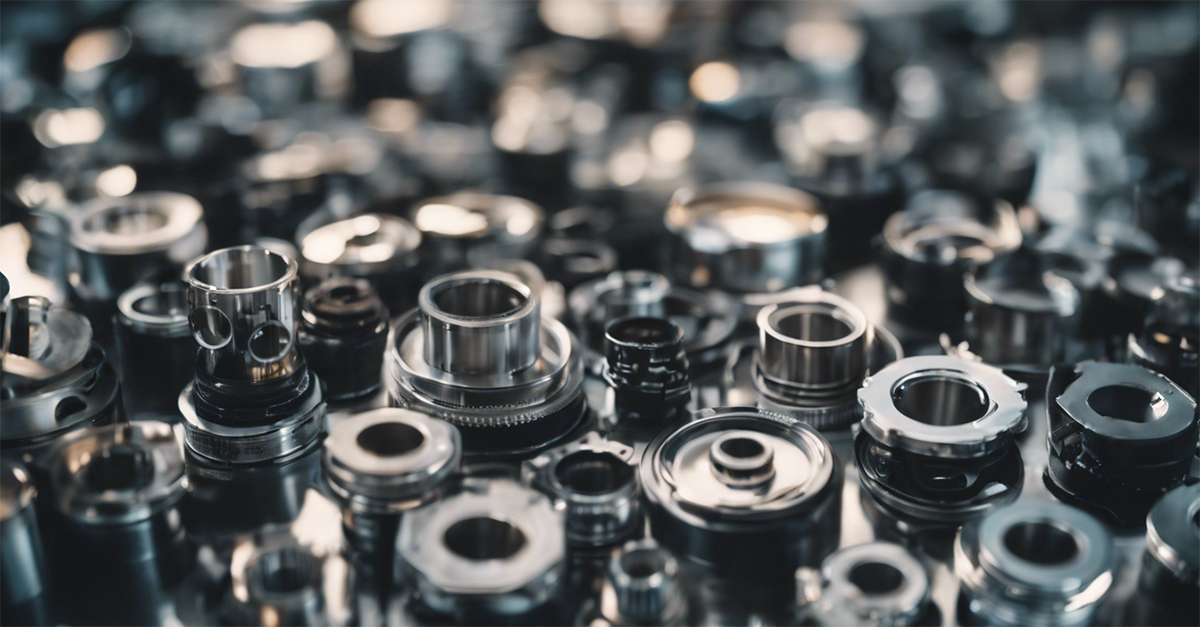

Hexavalent chromium (Cr(VI)) is a form of the metallic element chromium. It is commonly used in industrial processes such as electroplating, where a thin layer of chromium is deposited onto a metal part or component to improve its appearance, corrosion resistance, and wear resistance.

Key points about hexavalent chrome-plated parts:

- Process: The part is submerged in a solution containing chromic acid (H2CrO4) and an electric current is applied, causing the chromium ions to bond to the surface of the part.

- Appearance: Hexavalent chrome plating often results in a bright, shiny, and aesthetically pleasing finish.

- Corrosion resistance: The chromium layer helps protect the underlying metal from corrosion and oxidation.

- Wear resistance: Chromium plating can also improve the wear resistance and hardness of the surface.

- Health concerns: Hexavalent chromium is a known carcinogen and can cause serious health problems if inhaled or ingested. Strict safety regulations are in place for handling and disposing of hexavalent chromium compounds.

- Applications: Hexavalent chrome-plated parts are used in various industries, including automotive, aerospace, and precision manufacturing, for components such as hydraulic cylinders, shock absorbers, and decorative trim pieces.

Due to the health and environmental concerns associated with hexavalent chromium, there has been a push to develop safer alternatives.

Do you have a critical cleaning question for the experts at Alconox, LLC? Search TechNotes to see if it’s been answered before or Ask Alconox.

To request any Alconox, LLC detergents for free, please complete the questionnaire at Get Sample. For more information about any one of our Alconox, LLC detergents, consult the technical bulletin for each product. Or click here to access each of our detergent’s Safety Data Sheets