Ultrasonic Cleaning of Glass Molds (Detergents vs. Alkali)

Q. We have heard that Alconox is recommended for glass mold cleaning. Other than release agent, can the product also remove oxidation from the mold surface? And finally, why is the concentration on the Alconox detergent only 1-3% when we typically use concentrations of 20-30% when cleaning molds with sodium or potassium hydroxide based chemicals?

A. Alconox® Powdered Precision Cleaner is what we tradtionally recommend for mold release cleaning applications, but many also find Detonox® Ultimate Precision Cleaner to be particularly effective.

When it comes to removing oxidation…

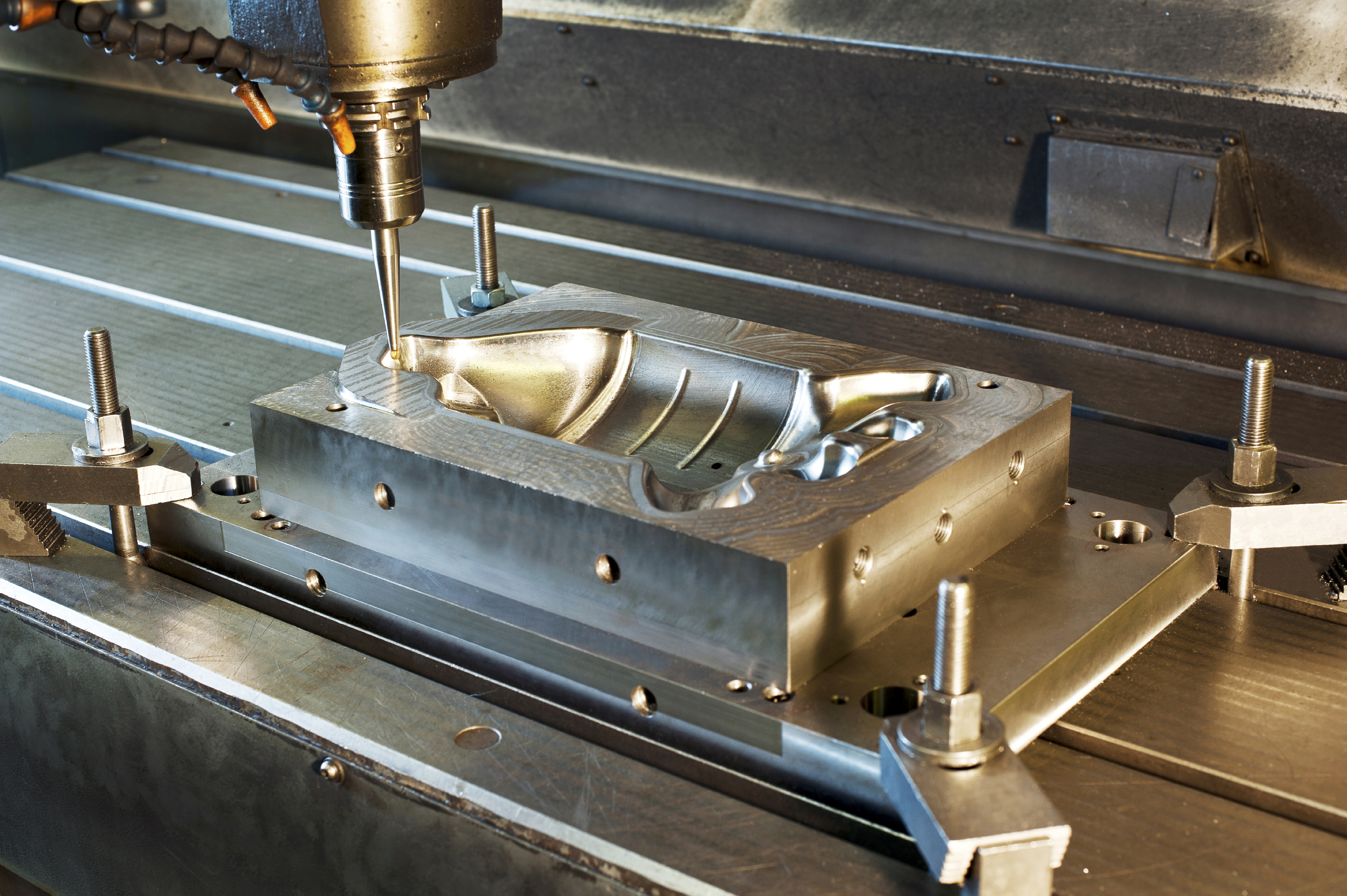

Industrial Ultrasonic Cleaning 101

Find answers to questions such as: What is ultrasonic tank cleaning? Which industries employ? What Alconox brands are ideal for ultrasonic tank cleaning?

Alconox Detergent for Antique Sink Restoration

Q. I work at a museum and my current project is to remove both oxidation of copper and what I assume are residues from calcareous water from a valuable, antique sink. From the XRF-analysis, I have identified the sink as having a copper base with a zinc-nickel plating. My primary concern is that I need to preserve the “used” and dull appearance on the sink and not achieve a shiny, “like new” result.

Cleaning Carbon Deposit Swirls On Alumina Parts

Q. Our parts, made of 99.5% alumina, have carbon deposits that show up after our brazing process. We do not use a flux for our ceramic parts; we high-temp fire a moly/manganese painted paste onto the ceramic. The part is then sent out for nickel plating to prevent corrosion of the moly manganese metallization areas. The next step is our brazing.

We are not seeing any spots on the parts before brazing, but as we continue through 5 brazing cycles and braze in a hydrogen/Nitrogen furnace with the cusil braze rings, we see black spots forming that show up as high-carbon deposits with the SEM data…

Removing Polishing Compound from Aluminum

Q. What Alconox product is ideal for manual removal of polishing compound from aluminum?

A. For manual cleaning of aluminum use a warm 2% Citranox solution to remove the polishing compound. Citranox will not harm the mirror finish on the aluminum. Rinse thoroughly after washing.