Prolonging Alconox Bath Life

Q. Is it possible to prolong the bath life of Alconox?

A. Yes. Start out with a stronger Alconox concentration. If using a 1% solution, use a 2% or possibly even 3% solution. After 1.5 weeks, add another 1.5% Alconox to the bath, especially if there has been make-up water added because of drag-out and evaporation. This regimen should allow successful cleaning for up to 3 weeks. It is not recommended trying to run an Alconox bath beyond 3 weeks, as these baths are prone to starting to grow microbes. Keep the bath covered when not in use and change out the bath every 3 weeks.

Cleaning Chromate Finished Zinc Plated Bolts

Q. I need to specify a cleaning protocol for chromate finished zinc plated bolts. The plater commented that any cleaning (except for a very mild one) can damage the chromate finish. The customer is concered about residual oils. My guess at a cleaning protocol would be: clean in ultrasonic bath, 2 min with 1% Alconox solution, rinse with de-ionized water. All we are doing is cleaning fasteners to be installed in a clean room. The level of cleanliness for these fasteners is a bit fuzzy. Does this sound reasonable?

A. Read the answer.

Cleaning Machined PTFE Parts

Q. I just received your chapter on cleaning SOPs and I look forward to reading it. In parallel, I was hoping to get your thoughts or a bit of advice on how to create and implement cleanliness specifications/processes for machined (PTFE) plastic parts. Cutting fluid for the machining center is basically a water soluble vegetable oil-based fluid. The use of this plastic manifold and cover is within an electro-mechanical-fluidic subsystem (“Delivery Module”). This delivery module accumulates a quantity of 59wt% Hydrogen Peroxide that has been … Click to Read The Full Question and Answer.

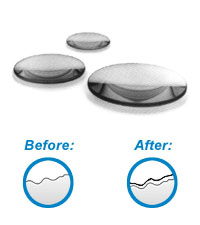

Cleaning Liquid Residue on Pipet Walls

Q. We are doing some experiments to quantify the amount of liquid residue on pipet walls before/ after cleaning. In practise, this would relate the accuracy of the pipet to its cleanliness. Could you inform us if the use of Alconox affects the amount of beading (of distilled water) on the walls of a brush cleaned and rinsed pipette, compared with the use of common dishwashing liquid?

A. Proper cleaning of a pipet will result in the designed amount of fluid being measured in a pipet according designed amount of beading resulting from the correct clean surface energy of the pipet and the surface tension of the fluid being measured. Typically pipets . . .

Optical Lens Cleaning

Q. How do you clean wax marks on optical lenses which are difficult to remove?

A. Use either 1% Alconox or Liquinox in a heated 160 deg F ultrasonic bath followed by a deionized water rinse to clean optical lenses during manufacturing.