Pharmaceutical Cleaning: Metaxalene

Q. Which Alconox detergents would successfully clean Metaxalene?

A. Metaxalene contains amide, ester and ether groups. The solubility is unknown. Alconox recommends using Liquinox or Citranox. For more information about Liquinox and Citranox, click to download each detergent’s technical bulletin and/or Material Data Safety Sheet (MSDS). You can also request a free sample by completing the questionnaire at Get Sample.

Cleaning Machine Oil with Liquinox

Q. We are cleaning straight machine oil off parts, followed by a Ozonics 203 dip. We have a vapor degreaser but stopped using it due to odors & EPA exhaust concerns. I plan to use Liquinox in a strong concentration to remove the residual oil and Ozonics 203. I plan to use the degreaser as a heated ultrasonic cleaner. What concentration would you recommend? This would be followed by our final u.s. cleaning using 2% Liquinox & dual cascading D.I. water.

Click for the answer.

Pharmaceutical Residue Removal: Iron Sucrose

Q. Which Alconox brand cleaners are suitable for the removal of iron sucrose?

A. Iron Sucrose is water soluble therefore it can be cleaned by either Citranox or Liquinox. Find out more about Citranox and Liquinox by downloading technical bulletins or MSDS at www.alconox.com.

Cleaning Bioreactors

Q. How can I clean bioreactors and do you have any SOPs you can offer.

A. Liquinox is typically used for cleaning bioreactors. A 1% solution of Liquinox (1.25 oz/gal or 10 mL/L) is used to soak and scrub the bioreactor. Learn More.

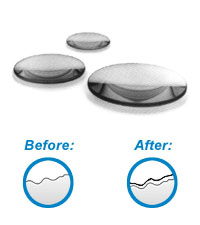

Optical Lens Cleaning

Q. How do you clean wax marks on optical lenses which are difficult to remove?

A. Use either 1% Alconox or Liquinox in a heated 160 deg F ultrasonic bath followed by a deionized water rinse to clean optical lenses during manufacturing.