Water Spots on Stainless? Improve Blowing Process

Q. White spots appear on our stainless steel parts the day after cleaning with Alconox. Right after we clean them, they are dry and visually clean. So, is this next-day residue from the Alconox detergent? If not, can you tell us why this is happening? A. It is fairly unlikely that visually clean parts have Alconox residues suddenly appearing the next day. In addition to Alconox being free rinsing, any residue that did not get rinsed for whatever reason, would be visible fairly immediately.

Most people in similar situations, even though the parts appear “dry and visually clean,” find that the spots are from water.

Do Your Cleaners Have Animal Origins?

Q. Does Alconox or any other recommended detergent have animal origins?

A. No. All Alconox, Inc. detergents are free-rinsing, biodegradable and contain no animal derived or genetically modified organism ingredients.

Removing Polishing Compound from Aluminum

Q. What Alconox product is ideal for manual removal of polishing compound from aluminum?

A. For manual cleaning of aluminum use a warm 2% Citranox solution to remove the polishing compound. Citranox will not harm the mirror finish on the aluminum. Rinse thoroughly after washing.

Removing Silicone Grease from Syringes

A faster method to remove silicone grease from syringes is to use very hot water for cleaning and very hot water for rinsing. Along with a powerful, free-rinsing, high emulsifying detergent,

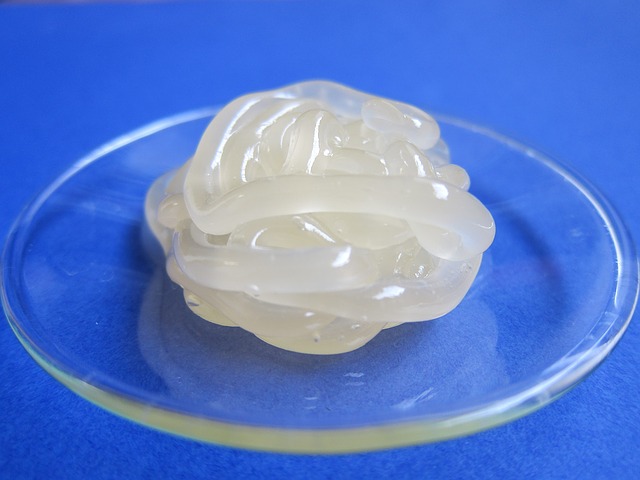

Medical Device Cleaning: Soft Acrylic Intraocular Lenses (IOLs)

Q: We are cleaning both hydrophilic and hydrophobic acrylic polymers. The cleaning process we use is mostly manual, involves no extended soaking, rather short contact with rubbing, and/or usage in an ultrasonic bath. Which of your products — Alconox, Tergazyme or Liquinox — would be most suitable for the cleaning of soft acrylic intraocular lenses (IOLs)?