Q. Our parts, made essentially entirely of alumina, have carbon deposits that show up after our brazing process. We high-temp fire an alloy painted paste onto the ceramic part. The part is then sent out for nickel plating to prevent corrosion of the alloy metallization areas. The next step is our brazing. We do not use a flux for our process.

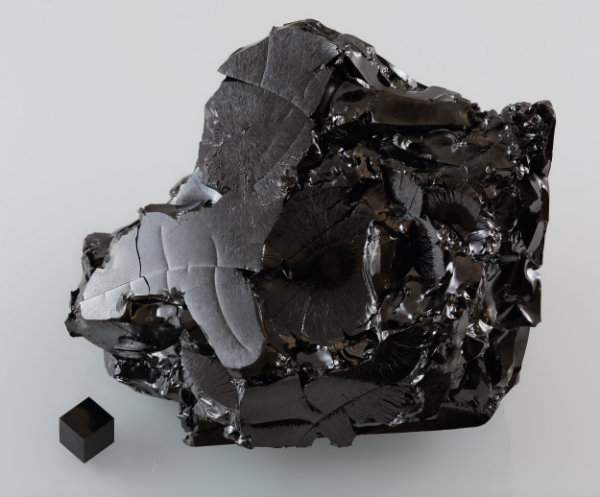

We are not seeing any spots on the parts before brazing, but as we continue through multiple brazing cycles, we see black spots forming that show up as high-carbon deposits with the SEM data. The spots often look like fingerprints and our current thought is that some chemical or residue may be left after the electro-nickel plating process or their post-process cleaning. What detergent would you would recommend for us to try in an ultrasonic tank?

A. Thanks for all the detail. It is truly helpful. If the parts are not being thoroughly cleaned prior to brazing, these swirls could be residual cutting oil. So the recommendation there would be a more robust cleaning prior to brazing as removing these subsequent to brazing would require mechanical and/or very aggressive chemicals if this is indeed the case.

At these high temps, any remaining oils, be they fingerprint oil, cutting fluid or similar, will get carbonized. As there are a few potentially reactive metals and alloys in play, an acidic detergent would be safest. Cleaning with Citranox® Liquid Acid Cleaner and Detergent after nickel plating, but prior to braze, should help significantly. A 5-10 minute ultrasonic cycle at warm temperature should be a good place to start (further optimization can always be done). Thorough rinsing with quality water (DI water for example) and quick drying (perhaps an isopropyl alcohol dip or lint-free wipe) is recommended. Finally using gloves and avoiding deposits of fingerprints or other oily, organic residue is important.

To request an Alconox, Inc. detergent for free, please complete the questionnaire at Get Sample. For more information about any one of our Alconox, Inc. detergents, consult the technical bulletin for each product. Or click here to access each of our detergent’s Safety Data Sheets.

Do you have a critical cleaning question for the experts at Alconox, Inc.? Search TechNotes to see if it’s been answered before or Ask Alconox.

Contact us any time: cleaning@alconox.com