Cleaning Proteins, RNA and DNA from Lab Equipment

Q. How can I clean proteins, RNA, and DNA from laboratory equipment?

A. Thank you for your question concerning cleaning proteins, RNA and DNA from laboratory equipment.

We will address each separately . . .

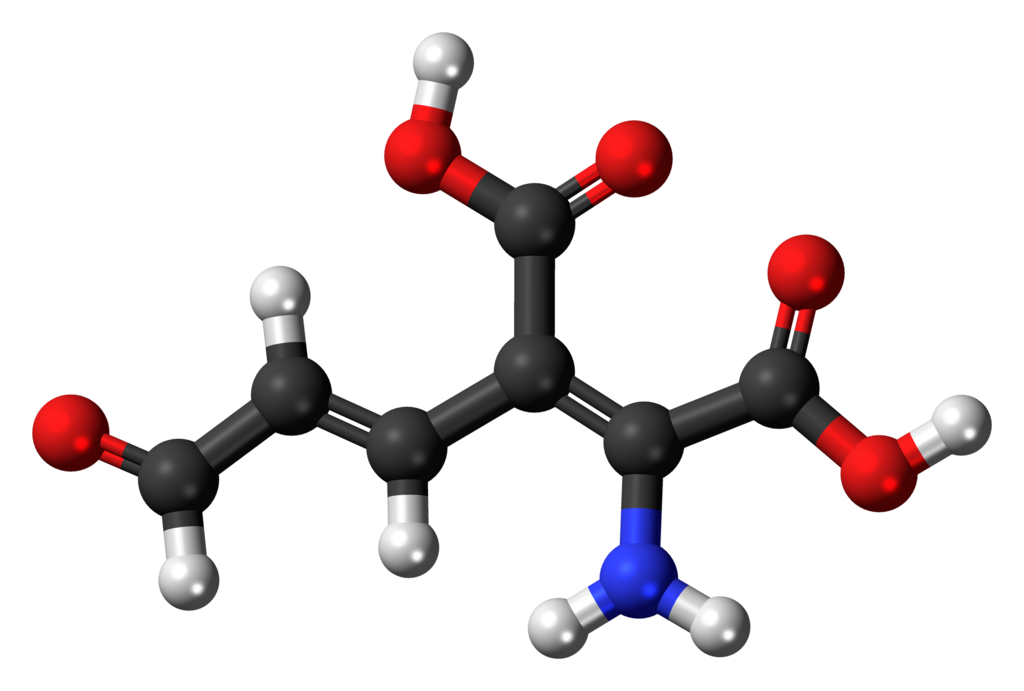

Advanced Cleaning Mechanisms: Oxidation

Oxidation or bleaching is one of the many cleaning mechanisms that a detergent formulator can bring to bear by formulating with appropriate ingredients. In cleaning, oxidation, or bleaching, changes the structure of a residue to render it more easily removed. Oxidation is loss….

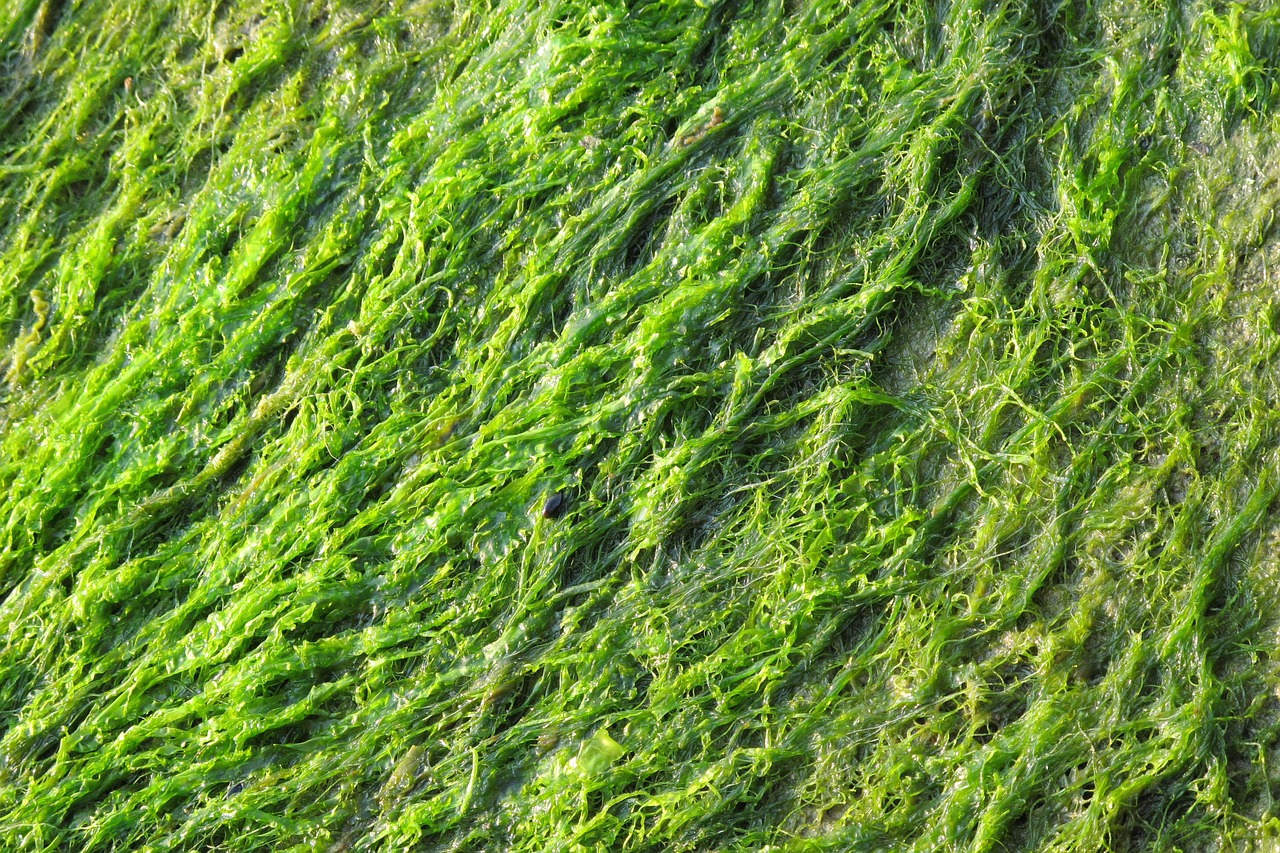

How to Clean Labware: Removing Algae

Q. We are a large energy company working with algae. It is proving tough to remove from glass and labware. We are using Liquinox detergent currently, which is good. Anything better? Eventually we would like to move to cleaning these in our washer.

A. Algae, and the viscous oils that you are working with, require not just powerful emulsifiers….

Biopharma Cleaning: Hormone Residue

Q. How can I clean residual hormone residue from our process lines and tanks?

A. For manual cleaning we would highly recommend TergazymeⓇ Enzyme Active Powered Detergent. It contains protein enzymes that can effectively break down protein based hormones along with powerful emulsifiers.

Cleaning Tissue Culture Flasks

Q: What is the recommended detergent for cleaning tissue culture flasks?

A: When it comes to maintaining a sterile and contamination-free environment in tissue culture labs, proper cleaning of tissue culture flasks is paramount. The task is not just about cleanliness; it’s about ensuring that there’s no residue left behind that could potentially impact the growth and health of cell cultures.