Replacing Hazardous Acids

Q: What can I use to replace hazardous acids below pH 1 cleaning?

A: Depending on exactly what you are using your acid cleaning to do, we may be able to help you.

Neutralizing Citranox for Waste Disposal

Q. We manufacture electronics and use Citranox to cleans oil off of a variety of machined parts. However, our Municipal Water District does not allow the disposal of spent Citranox. Can you recommend a neutralization procedure?

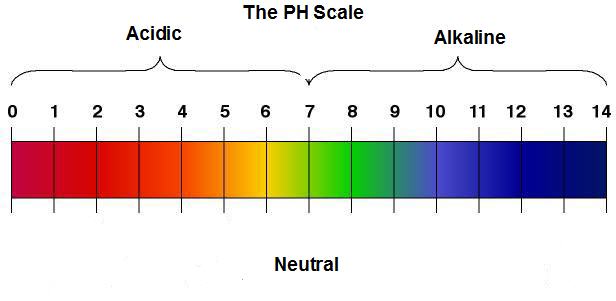

A. You will need 0.14 lbs, 0r 2 ¼ oz of baking soda (sodium bicarbonate) to neutralize a gallon of un-used 1% Citranox solution to a pH near 7. Note that some of the acidity in Citranox may be depleted …

Improving DI Water Wettability

Q. We are looking for a low concentration surfactant to improve DI water wetting to polycarbonate and stainless steel during an aerated flushing operation for removal of sub-micron surface particles. Our parts are cleaned before assembly – we need to improve a DI-water flushing operation that is meant to remove sub-micron sized surface particulate from inside an assembled gas path (tube). How can we improve wettability of DI water?

Stripping Silicone Coating

Q. I need to strip a silicon coating from a small coaxial cable. We currently use a heated ultrasonic cleaner with about 1.5 gallon reservoir with Dynasol as the solvent. We need an explosion proof heated ultrasonic cleaner or a recommendation.

A. If you want to avoid having to use an explosion proof ultrasonic with a solvent like Dynasol, I recommend you use . . .

Critical Cleaning Challenge? There’s an App for that…

Have a critical cleaning challenge? There’s an App for that!! Alconox, Inc. the critical cleaning experts, launches its first ever application to put your cleaning needs and detergent selection information right at your fingertips.