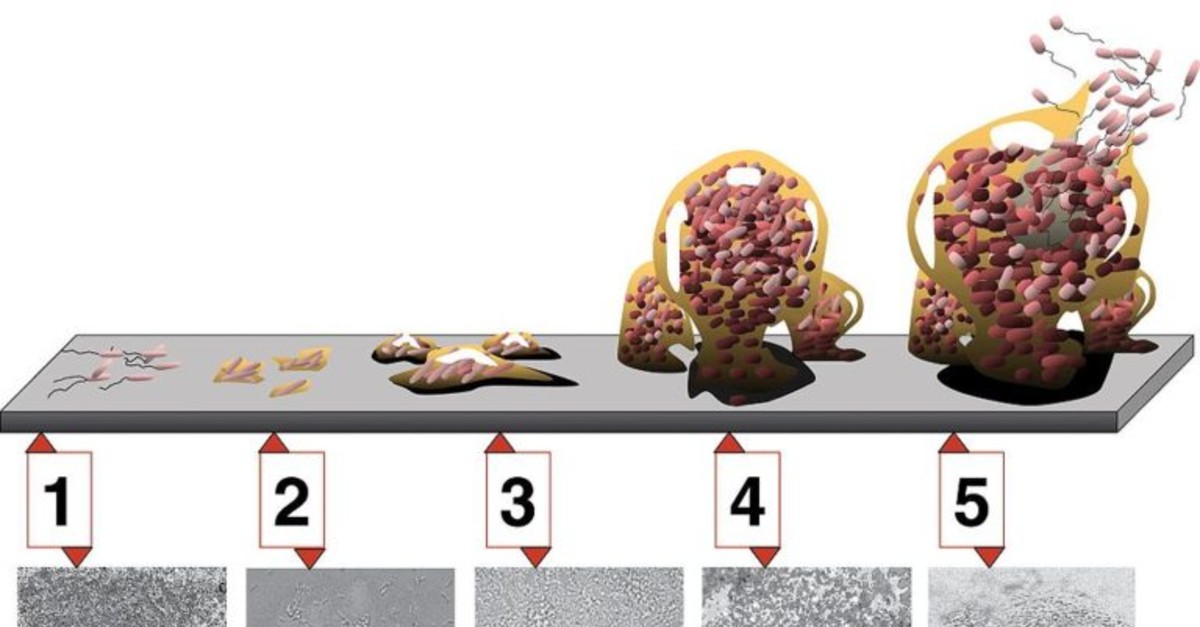

Advanced Cleaning Mechanisms: How to remove biofilm

In order to “kill off” any microbial residue, a cleaning and removal of inanimate and organic matter is a must. This would follow with the disinfecting, “kill” step if you will, with an EPA registered disinfectant. To prepare for removal of biofilms on stainless steel via a registered disinfectant, use a two-step process of Solujet alkaline cleaner followed by Citrajet acidic cleaner. Or consider our highly effective enzymatic detergent for use in manual applications including scrubbing, soaking, sonciation or low agitation cleaning in place.

How to: Reduce Cleaning Time

Q. What can we do to reduce cleaning time? We want to be as optimal and thorough in our cleaning as possible.

A. At Alconox Inc we recognize that manual cleaning may take minutes, spray cleaning seconds, and soaking may take hours, possibly overnight, to achieve comparable cleanliness. Read more….

One Detergent to Clean Them All?

Q: We are advising a mid-sized pharmaceutical company. If we use multiple cleaning agents within a facility, the cleaning program may be a bit difficult to manage (chances are that the operators may use the incorrect cleaning agent for the product) and also the cleaning validation will be a more complex exercise. What would you recommend for general cleaning? Which is preferred between acidic and alkaline cleaning agent to start with?

A: Thank you for your inquiry for a multi use detergent as this is certainly a uncommon question. Learn more….

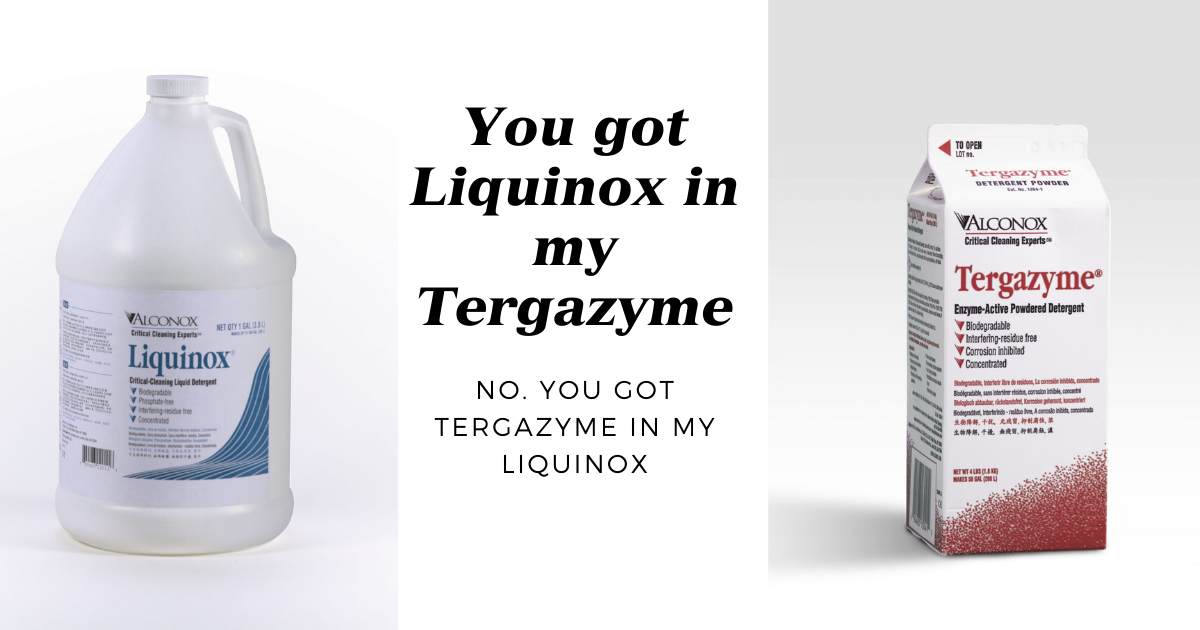

Improving Tergazyme Detergent

Q: We have an array of tough proteinaceous and oily residues. I am considering adding a non-ionic surfactant like Triton X-100 to a normally prepared solution of 1% Tergazyme, is there any data about whether or not that would damage the enzyme? Is it a way of improving Tergazyme?

See You At PACK EXPO in Las Vegas

PACK EXPO is happening September 27-29 in Las Vegas.

Reconnect at PACK EXPO Las Vegas and Healthcare Packaging EXPO and experience the latest innovations to move your business forward.

We are at booth SL-6523.