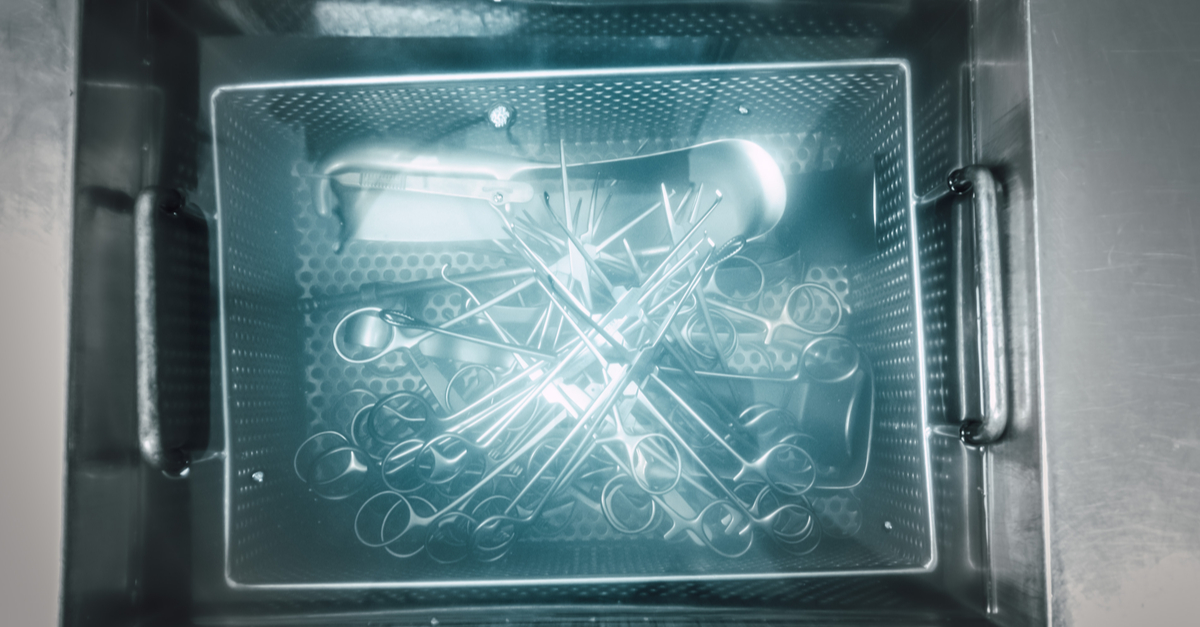

Ultrasonic Cleaner for Mixed Metal Baths

Q. We are interested in a cleaner that will perform well for mixed metal ultrasonic baths. We are cleaning titanium and cobalt chrome. What can you recommend?

A. As a general rule, mixed metal baths should be avoided. When metals are far enough apart on the galvanic potential scale, batteries can form and the plating out of metal oxides can result, manifesting in dark deposits. This occurs when you clean active metals in electrical and electrolyte solutions in contact with another metal at a different galvanic potential.

Determining When To Change Your Detonox Bath

Q: We are using Detonox detergent in our ultrasonic baths and are loving it. We use a visual inspection method (cloudiness of solution) to determine when to change the bath and are moving to conductivity and pH. It appears pH stays constant regardless of concentration?

A: As a broad statement, detergent concentration does very little to affect pH due to buffers, as well as salts, micelles, and other constituents. A pH meter wouldn’t be used to control for concentration on anything but very gross scales.

Ultrasonic Cleaner for Parts and Towels

Q. I’m looking for a cleaning solution to use in our industrial ultrasonic cleaner that is similar to the old style competitor detergent. We use it occasionally for general cleaning, removal of machining oils, cleaning for high vacuum use, and to lightly etch the oxides off of copper. Would you recommend Alconox or Liquinox detergent? How long would a pre-mix of the formulations last before degrading? Could we also use this for washing microfiber towels and foam sponges that have various waxes, polymer sealants and oils on them?

Choosing Temperature for Ultrasonic Parts Cleaning

Q. How to determine appropriate temperature to clean parts with ultrasonic cleaner?

A. In general, every 10 deg C you go up in temperature doubles the cleaning speed. The faster you want to clean the hotter you should get.

There is a theoretical optimal ultrasonic cavitation temperature at around 70 deg C depending on the exact concentration of detergent. Even though in theory cavitation…

Reducing Foam in Ultrasonic Cleaning

How do we go about reducing foam suds in our 1% Liquinox ultrasonic bath? We have 3 ultrasonic tanks in our series process. Bath 1 has the 1% solution. Bath 2 and 3 are a rinsing cascade system with RO water only. The foam is building up in tank 1 and then transfers to tank 2.